Pharma makes progress on continuous processing

pharmafile | September 24, 2013 | News story | Manufacturing and Production | continuos processing, pharma

The drug industry has lagged behind other sectors in adopting more efficient manufacturing, but there are signs that one key shift – from batch to continuous processing – is starting to gain traction.

Eli Lilly for example says that there are elements of continuous processing in the production of almost all of its medicines, but it plans to have installed and demonstrated four separate continuous processing platforms by early next year.

Continuous processing is used in most other large-scale manufacturing – including food production, petroleum refinement and water treatment as well as glass and iron ore production. In the latter cases the machinery operates almost non-stop for years at a time.

Pharma has been nervous of taking the plunge however, and has stuck largely to the traditional approach of producing batches of ingredients via a series of reactions with isolation of solid intermediates before the end-product is isolated and placed in bulk drums.

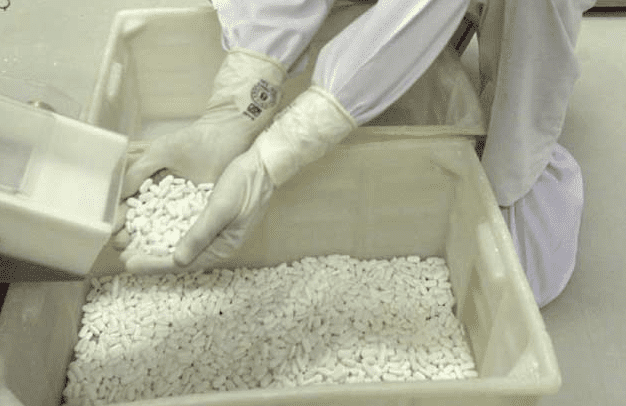

The active pharmaceutical ingredient is then processed into a granular form, which is also collected in bulk containers, with drying and other stages carried out ahead of the material being compressed into tablets and coated.

Continuous processing removes the intermediate collection and packaging steps by allowing ingredients to move through the production line in manner akin to the assembly line seen in other industries, according to Lilly’s Bret Huff, who have a keynote presentation on the firm’s aspirations in this area at the American Chemical Society (ACS) annual meeting in early September.

“The difference between batch and continuous processing is somewhat like the difference between a ferry boat and a bridge for getting cars and people across a river,” said Huff. “A bridge is typically open, with the flexibility to meet demand, without having a line-up of cars waiting for the next trip across.”

Quality-control testing and other monitoring is integrated into the continuous-flow operation, rather than being carried out as each batch finishes, and this means that problems can be identified and corrected before too much material is wasted.

Moreover, doubling the number of tablets produced in a batch process would typically also require doubling the amount of production equipment, said Huff. In contrast continuous production can be dialled up more easily to increase the output to meet demand.

He told ACS delegates that with batch processing small amounts of the ingredients inevitably are lost and wasted at each step, with other inefficiencies also taking their toll, and it may take days or weeks to finish each batch of medicine.

Transitioning from batch to continuous mode of operation will require process re-designing and regulatory approval in the majority of the cases, so there is a logistical and bureaucratic barrier to adoption despite the benefits as well as technical barriers to overcome to ensure quality and purity.

Lilly is not alone in making a shift to continuous production. GlaxoSmithKline said earlier this year that it would invest $50 million to install and validate commercial-scale continuous processing equipment at a plant in Singapore that makes the antibiotic amoxicillin, while Novartis recently announced plans to build a commercial-scale continuous processing facility by 2015.

Pfizer said this month it has already evolved towards a hybrid model between continuous and batch processing, with continuous approaches in areas such as coating and crystallisation sitting alongside traditional batch systems.

Meanwhile, the PROMIS research centre in Finland completed the construction of a continuous processing pharmaceutical production line earlier this year – the only one of its kind in Europe – that will provide R&D on the use of continuous processing of solid dosage form pharmaceuticals.

24-hour biologics

Other groups are starting to explore the benefits of continuous processing in the manufacture of medicines, with scientists at the Massachusetts Institute of Technology (MIT) in the US trying to develop a rapid production system for biologics based on the technology, that could be used to provide drugs in remote settings or even on the battlefield.

The team, headed by Christopher Love, has just been awarded a $10.4 million grant from the Defense Advanced Research Projects Agency (DARPA) to make a miniature biologic processing unit that could manufacture small amounts of a protein or antibody-based drug in as little as 24 hours, rather than the six to 12 months required for commercial scale production.

One barrier to adoption cited by some in the pharma industry is a lack of guidance from regulators, although Huff indicated in his ACS presentation that the FDA “has been assuring companies that there are no scientific, regulatory or other hurdles to adopting continuous processing”.

He concluded: “The approach has many benefits, including reduced costs of making medicines, faster production and greater flexibility to tailor production to demand.”

Phil Taylor

Related Content

LGC Group opens $100M Organic Chemistry Synthesis Centre of Excellence

LGC Group, a life sciences company, has opened its new Organic Chemistry Synthesis Centre of …

Johnson & Johnson announces successful results from trial for myeloma treatment

Global healthcare company, Johnson & Johnson, announced that analysis of its Darzalex (daratumumab) therapy showed …

Bend Bioscience adds commercial spray drying facility to Georgia site

Bend Bioscience has announced the addition of a commercial-scale spray dryer and a Gerteis dry …